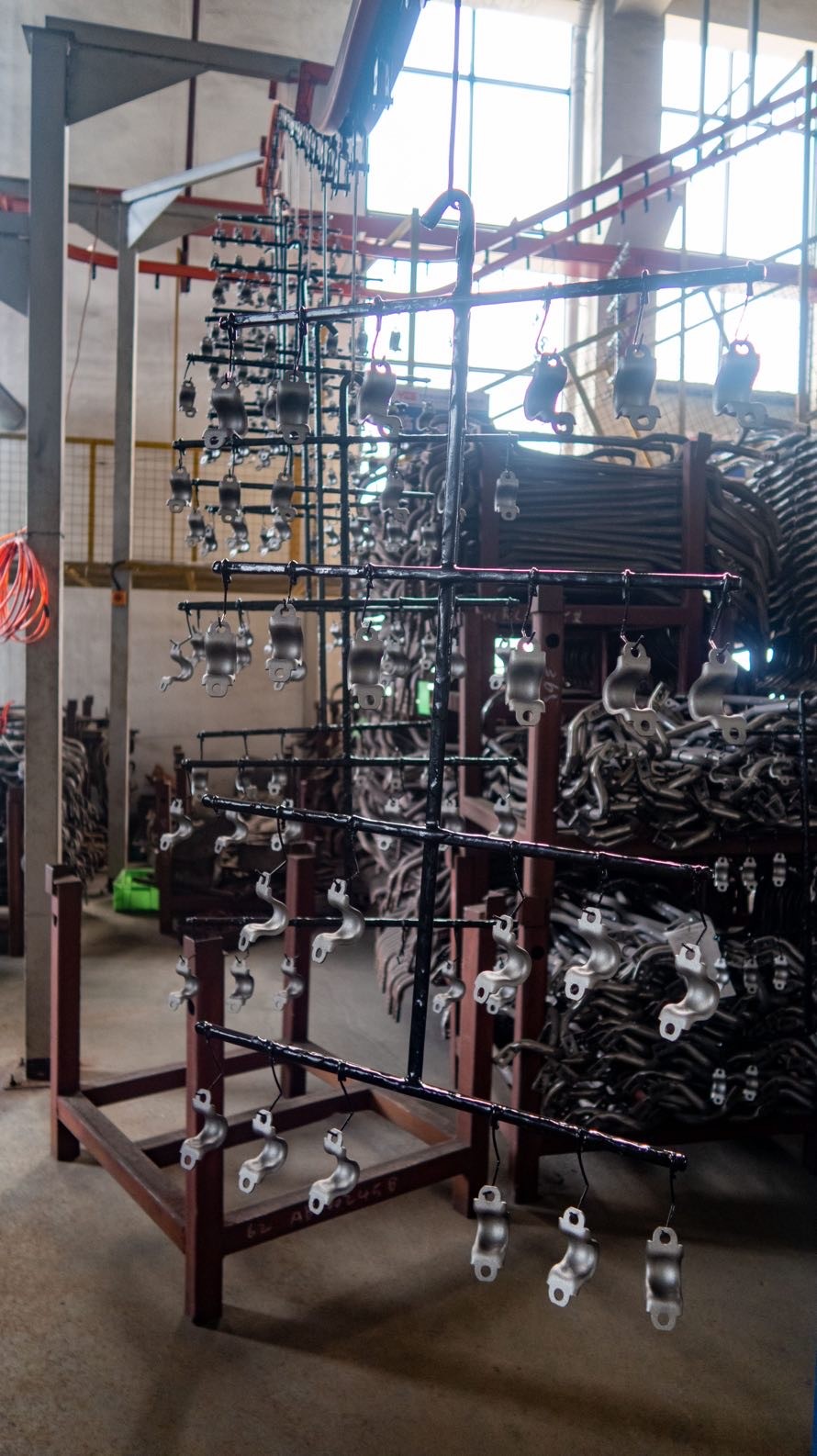

Preparation Process for Product Painting

Before any product undergoes the painting process, we prioritize meticulous preparation to ensure optimal results. This essential phase involves several key steps:

1. **Cleaning**: Each product is thoroughly cleaned to remove any dust, grease, or impurities. This ensures that the surface is ready for paint adherence.

2. **Inspection**: Our quality control team conducts a detailed inspection to identify any defects or imperfections. This step is crucial for maintaining high standards of quality.

3. **Sanding and Surface Preparation**: We sand the surfaces to create a smooth texture, which enhances paint adhesion. Any rough edges or irregularities are addressed during this step.

4. **Priming**: A primer is applied to provide a uniform surface and improve the durability of the final paint layer. This step is vital for achieving a long-lasting finish and vibrant color.

5. **Drying**: After priming, products are allowed to dry completely, ensuring that the surface is ready for the next layer of paint.

6. **Masking**: Areas that should remain unpainted are carefully masked off. This prevents any overspray and ensures clean lines in the finished product.

By following these meticulous preparation steps, we ensure that our products achieve the highest quality and aesthetic appeal once they are painted. Our commitment to excellence in this phase lays the foundation for a superior final product.

+86-571-88843231

+86-571-88843231